Material Handling Case Studies

See How UNEX Solutions Transform the Supply Chain.

Our material handling case studies provide an informative and insightful look into the significant impact UNEX solutions can have on your operation. Browse our case studies to learn more about applications where UNEX solutions have made a huge impact across the supply chain. Whether you’re in need of dynamic storage solutions like carton flow, flow racks, high-density storage, or you’re looking to improve material flow throughout your facility with portable and permanent gravity conveyors, our case studies will help you discover what’s possible when you work with UNEX. Contact us to connect with a product specialist who can help you create the solutions required for your unique needs. UNEX provides full and free engineering support on all projects!

High-Density Storage

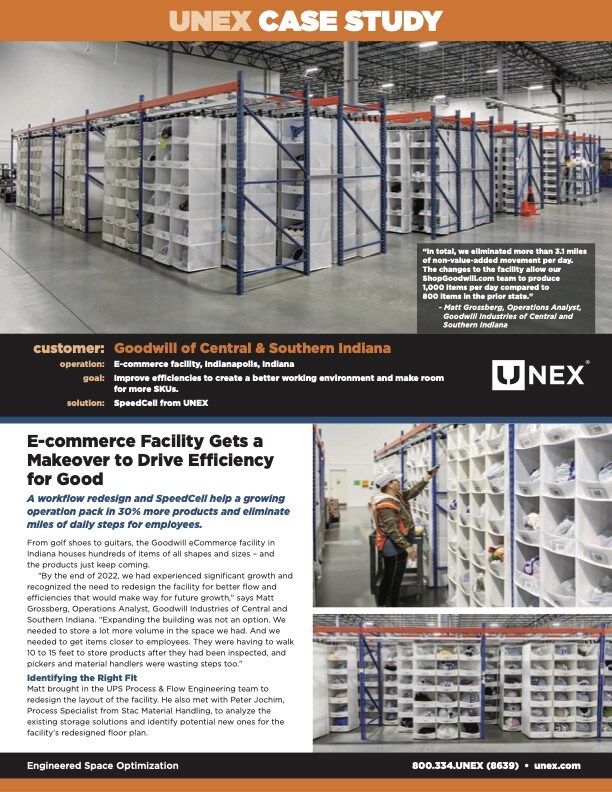

SpeedCell high-density storage compresses rows of shelving into highly organized, space-saving storage that increases SKU capacity, improves pick speed, and reduces travel time. Browse the case studies to see how operations turned unused space into efficient pick zones and boosted accuracy without expanding their footprint.

Goodwill

Overton’s

Carton Flow

UNEX carton flow maximizes productivity by ensuring FIFO inventory rotation, reducing picker strain, and delivering up to 150% faster throughput in order fulfillment environments. Explore the case studies below to see how real companies used carton flow to overcome space constraints and speed up their pick operations.

Atlas Distributing

Fresh Direct

Cutter & Buck

Diversity Vuteq

ThermoFisher Scientific

Grocery Distributor

Capital Candy

Capital Candy 2.0

Pine State Trading Co.

Southern Glazer's

Food Wholesaler

Smart & Final

Maletis Beverage

Flow Racks

FlowCell flow racks provide modular, durable, and ergonomic storage that supports Lean initiatives, helping manufacturers and distributors save space, cut labor costs, and boost picking efficiency. The customer stories below highlight how organizations reconfigured workflows with Flow Racks to increase output without expanding their footprint.

Darn Tough Vermont

HelloFresh

BraunAbility

Daimler Trucks

Toyotetsu

Aubuchon Hardware

Adient LLC

George J. Falter

Android Industries

Conveyors

UNEX Gravity Conveyor systems are custom-built for smooth product movement, cutting downtime and labor costs while improving throughput in assembly, warehousing, and logistics operations. Read the case study below to learn how facilities used Gravity Conveyors to eliminate bottlenecks and streamline material handling.

Williams Distributing

Connect with an Expert

Get in touch with our team of space optimization experts to learn more about our industry-leading solutions.