Gravity Conveyor

Durable, efficient gravity conveyors move loads through a facility. Our extensive line of roller and wheel conveyor solutions that are easy to install, made to order, and proven to increase warehouse efficiency and throughput significantly.

Gravity Conveyor Benefits & Features

Eliminate costly malfunctions and equipment damage with durable, low-maintenance gravity conveyors engineered to keep your operations flowing seamlessly. Designed to meet dynamic facility needs, UNEX gravity conveyors provide lasting performance and can be customized to fit your specifications. From tailored lengths and widths to specialized roller centers and wheel patterns, our solutions adapt to your unique requirements.

Benefits

-

Replace high-maintenance conveyor systems with rugged, low-maintenance gravity roller conveyors

-

Enhance throughput and streamline material handling across your facility

-

Gain access to an extensive line of roller and wheel conveyor solutions

-

Save time and money with conveyor lengths manufactured to the inch, providing flexibility for almost any situation

Features

-

All steel construction for increased durability

-

Optional aluminum construction

-

Available in multiple standard widths

-

Available in straight lengths up to 144″

-

45° and 90° curves available

-

Numerous spur options to suit most layouts

-

Manual and spring assisted personnel gates

-

Available with square cut ends for permanent installations, notched ends for dropping onto beams, and coped ends for temporary hook and bar layouts

-

Straight and curved sections are available for ultimate flexibility

-

End treatments, including package stops, impact plates, and hook and bars

-

Height adjustable H-Supports for permanent installation

-

Powder-coated Steel Tripod supports for temporary installs

-

Easy to install

Connect with an Expert

1.38" Diameter Roller Gravity Conveyor (JRS)

Ideal for conveying light-weight packages in operations that require portable or temporary conveyor lines such as warehousing or shipping areas.

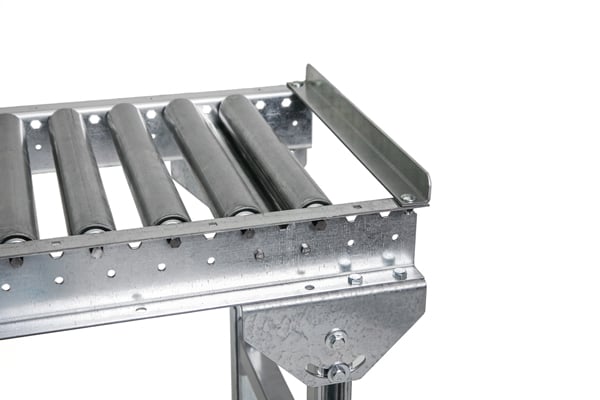

1.9" Diameter Roller Gravity Conveyor (MRS)

Ideal for conveying medium-weight packages in permanent installations.

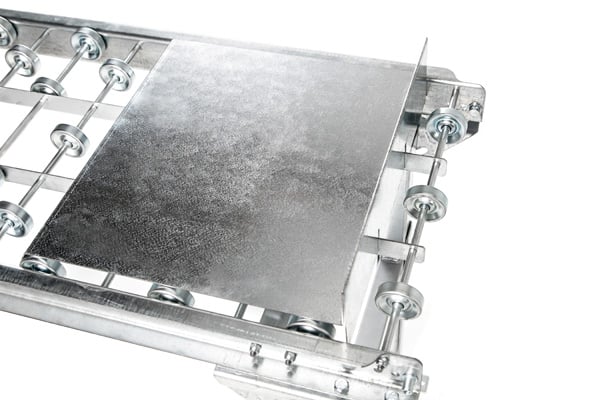

Skatewheel Gravity Conveyor (SW)

Ideally suited to convey lightweight packages in operations that require portable or temporary conveyor lines like warehouses and shipping areas.

Options and Accessories

Spurs

Gates

Supports

Package Stops

Fixed Angle End Stop

Roller Stop

Guard Rail

Ball Transfer Tables

Spurs

Used to transfer product from one conveyor line to another smoothly or for merging or diverging applications.

Gates

Available for SW, JRS, and MRS series conveyors, spring-assisted gravity gates provide a way for personnel or equipment to pass through the conveyor line.

Supports

“H” type permanent floor supports and portable tripods provide multiple height and weight options and offer robust and dependable support.

Package Stops

“Dead” type package stops work well on skatewheel (SW) or 1.38″ (JRS) conveyor sections.

Fixed Angle End Stop

Angle end stops mount from the end of the conveyor and bolt to the top flange of conveyor side channels.

Roller Stop

Roller stops allow loads to be supported while pulling product from the end of the conveyor section.

Guard Rail

Use with SW, JRS, and MRS series conveyors; also available for straight and curved sections and one or both sides.

Ball Transfer Tables

Our multidirectional ball transfer tables help position material precisely and help make tight turns when curves aren’t an option.

Who Can Benefit from Gravity Conveyors?

Gravity Conveyors are a versatile solution designed to optimize material handling processes across various industries, offering an efficient and cost-effective method for moving products. These conveyor systems can improve operations in:

- Manufacturing Facilities: Facilitate the smooth transfer of goods along production lines, enhancing workflow efficiency and minimizing labor costs. Gravity conveyors help accelerate material movement between workstations, reducing manual handling.

- Warehouses & Distribution Centers: Gravity conveyors create organized pathways for product flow, enhancing order picking, packing, and shipping processes. They're particularly useful in creating efficient packing stations and streamlining fulfillment operations.

- Order Fulfillment Centers: Customize workstations with gravity conveyors to enhance flow-through picking, packing, and kitting processes. These solutions boost productivity and allow order fulfillment teams to manage high volumes of orders with greater accuracy and speed.

- Retail Operations: Streamline inventory management by using gravity conveyors in retail warehouses or stock areas to move products from receiving to storage or display. This improves stock rotation, reduces manual transport, and ensures smoother replenishment processes.

- Shipping & Receiving Areas: Gravity conveyors streamline loading and unloading processes, facilitating smooth transitions between trucks and warehouse storage areas. This speeds up operations and reduces potential bottlenecks.

How Gravity Conveyors Support Efficient Material Handling

UNEX Gravity Conveyors are designed to enhance material handling processes, enabling businesses to improve efficiency, reduce costs, and optimize their operations. These versatile conveyor systems support efficient material handling in the following ways:

- Cost-Effective Movement: Gravity conveyors utilize the natural force of gravity, eliminating the need for powered systems and reducing energy costs while providing smooth, continuous product flow throughout the facility.

- Improved Ergonomics: By keeping products at accessible heights and reducing the need for manual lifting and carrying, gravity conveyors enhance worker ergonomics, potentially decreasing fatigue and injury risks.

- Increased Throughput: The continuous flow provided by gravity conveyors speeds up processes such as order picking, packing, and shipping, leading to increased throughput and productivity in warehouses and distribution centers.

- Adaptable Solutions: UNEX offers a wide range of options, including different lengths, widths, and roller or wheel styles, allowing businesses to create custom conveyor systems that seamlessly integrate into their existing infrastructure and adapt to changing needs.

Companies That Choose UNEX

Capital Candy

George J. Falter

Williams Distributing

Carton Flow and Conveyor Solutions Maximize Pick Productivity at Capital Candy

Distributor Reduces Pickers by a Third, Maximizes Space and Efficiency with Roller Rack and Gravity Conveyor

Goodbye, Awkward Furniture Dollies. Hello, Smooth-Flowing Gravity Conveyors from UNEX.

Resources

Explore AllMore To Consider

Pallet Track

Durable pallet track rollers or wheel rails create a dynamic pallet flow system designed to optimize flow.

SpanTrack Lane

Efficient, durable carton flow rollers that drop into existing structures to create the ultimate carton flow rack system.

SpanTrack Wheel Bed

Superior, made-to-order carton flow beds that drop into existing structures to create flexible storage for cartons of varying widths.

Connect with an Expert

Get in touch with a space optimization expert to learn how our solutions maximize productivity and optimize warehouse space.