FlowCell Modular Flow Racks

FlowCell modular flow racks are storage units and workstations designed for a facility’s unique operation. Our durable, portable flow racks maximize pick efficiency and space for lineside storage, sub-assembly stations, supermarket racks, modular mobile carts, and more.

FlowCell Benefits & Features

FlowCell provides a flexible, ergonomic solution that supports Lean principles. Modular flow racks organize your inventory, accelerate pick productivity, and eliminate waste.

Benefits

-

Increase space utilization by up to 50%

-

Boost production efficiency by up to 30%

-

Minimize reaching and improve ergonomics by reducing injury and fatigue

-

Create reconfigurable, flexible storage to accommodate line and process changes

-

Ensure FIFO inventory rotation

-

Keep the factory floor organized — totes and boxes can be stored in return lanes rather than on the floor

Features

-

Reconfigurable, adjustable units for each unique operation

-

Clean, organized sightlines

-

Engineered to angle parts toward the picker

-

Heavy gauge steel construction

-

Quick assembly (under 1 hour)

Connect with an Expert

Workstation

Shown with three levels of SpanTrack Bed (1.6" Hex Hub) and tilted pick tray.

Lineside

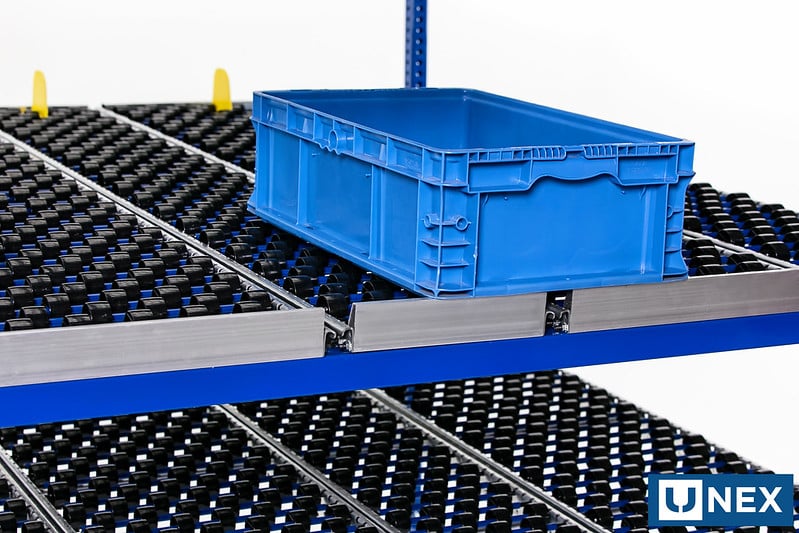

Shown with three levels of SpanTrack Lane (.75" Aluminum) and casters.

Mobile Unit

Shown with three levels of SpanTrack Bed (1.6" Hex Hub) and casters.

Stationary Unit

Shown with three levels of SpanTrack Lane (.75" Aluminum).

Who Can Benefit from FlowCell Modular Flow Racks?

FlowCell modular flow racks are designed to streamline various processes across different industries, offering a flexible and efficient storage and picking solution. These flow racks can benefit the following industries:

- Manufacturing: Flow racks enable optimized and accessible storage and picking areas for manufacturing lines, aligning with lean manufacturing principles by reducing waste and improving accessibility.

- Order Fulfillment Centers: FlowCell can create customized workstations for flow-through, picking, packing, and kitting, streamlining order fulfillment processes based on unique warehouse facility needs.

- Retail Backrooms & Order Pick Up: These modular flow racks can accommodate space constraints in retail backrooms or pick-up areas, organizing inventory or staging orders at ergonomic elevations with flexibility to adapt to changing needs.

- Third-Party Logistics Facilities: FlowCell offers an agile and cost-effective warehouse storage solution for 3PL providers, accommodating various product sizes and quickly adapting to different client contracts, even in smaller footprints or height-restricted areas.

How FlowCell Supports Lean Manufacturing Principles

FlowCell modular flow racks are designed to align with the core principles of lean manufacturing, enabling manufacturers to eliminate waste, improve efficiency, and enhance quality control throughout their operations. These dynamic storage systems support lean practices in the following ways:

- Elimination of Waste: Flow racks streamline first-in-first-out (FIFO) inventory processes, increase visibility, and reduce unnecessary movement and downtime by keeping parts accessible at the pick face within a condensed footprint.

- Continuous Flow: With inventory flowing freely from one process to the next, flow racks facilitate continuous flow to the assembly line, whether set up for lineside storage, on mobile carts, or integrated into workstations.

- Just-In-Time (JIT) Production: The flexible, modular design of flow racks allows precise layout and inventory flow customization, enabling manufacturers to maintain perfect synchronization between supply and demand for true just-in-time production.

- Built-in Quality: By keeping components organized in smooth-flowing, accessible lanes, flow racks make it easier to access parts, reduce damage risk, and facilitate consistent quality control in line with lean's 5S system (sort, set, shine, standardize, sustain).

Build a Flow Rack with Our Free Design Tool

Build FlowCell modular structures from scratch or choose from existing configurations. These durable, dynamic units will maximize space and step up productivity.

Companies That Choose UNEX

Daimler Trucks Components & Logistics

HelloFresh

Truck-Building Business Picks Up Speed, Space and Accuracy with UNEX Solutions

HelloFresh Makes Room for Growth – and Future Appetites, Thanks to FlowCell

Resources

Explore AllMore To Consider

Roller Rack

Pre-engineered gravity flow racks are proven to speed pick rates, increase space utilization, and ensure FIFO rotation.

SpeedCell

A dynamic high-density storage system that optimizes storage space within your racks, increasing storage density by up to 60% for faster and more accurate picks.

SpeedCartt

A flexible and fast mobile order picking cart ideal for restocking, order fulfillment, seasonal demands, and more.

Connect with an Expert

Get in touch with a space optimization expert to learn how our solutions maximize productivity and optimize warehouse space.