Warehouse Storage Solutions Engineered For Growth

Configurable warehouse storage built to accelerate productivity and evolve with your supply chain.

Discover Smart Space Solutions That Transform the Supply Chain

As consumer demand and expectations grow, companies across the supply chain need to adapt to remain competitive. UNEX works with manufacturers, distributors, retailers, and logistics companies to unlock their facilities’ full potential by maximizing space utilization with our industry-leading storage solutions. Durable, flexible, and space-efficient UNEX solutions are proven to:

Optimize Space

UNEX solutions condense and organize storage space within a facility’s existing footprint to reduce the need to expand or acquire new locations.

Increase Efficiency

Dynamic storage solutions increase overall facility efficiency by reducing pick paths and improving assembly, picking, packing, and shipping processes.

Improve Productivity

Travel times are reduced and costly errors like mispicks are mitigated when inventory is organized, and parts and products are stored according to throughput.

Drive Revenue Growth

By increasing space utilization, efficiency, and productivity, facilities experience major operational cost savings that increase profitability.

Industries Utilizing UNEX Storage Solutions

UNEX specializes in building engineered-to-order storage solutions that help operations in various industries meet and surpass their efficiency goals. No matter what kind of facility you run, we can tailor a solution to align with your unique needs.

Solutions for Every Application

Explore our innovative space-saving storage solutions for a diverse range of applications.

Storage

Discover space-saving, storage solutions for your warehouse.

Picking

Maximize picking productivity with solutions designed for slow-to-fast moving products.

Packing & Assembly

Streamline packing and assembly activities on the manufacturing or warehouse floor.

UNEX Space Optimization Solutions

Our industry-leading solutions are made-to-order, targeting your facility's specific pain points.

Carton Flow

Flow Racks

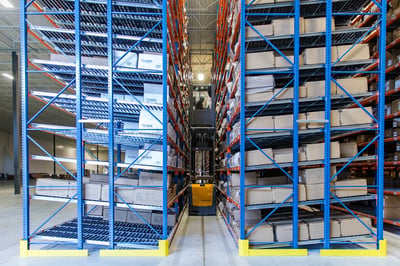

High-Density Storage

Conveyors

Carton Flow

Carton flow solutions like SpanTrack - The Original Carton Flow Track - effortlessly drop into existing structures to maximize space and create a robust flow system for any operation.

Flow Racks

Modular flow racks and gravity flow rack systems increase space utilization, accelerate productivity, improve ergonomics, eliminate waste, and lower operational costs.

High-Density Storage

High-density storage systems provide maximum capacity for fast, safe, and accurate order picking that saves operations space, time, and money.

Conveyors

Flexible, rugged, and low-maintenance gravity conveyors and pallet flow systems designed to support a variety of products and SKUs keep orders organized and moving seamlessly throughout your facility.

About UNEX

Since 1964, UNEX has been manufacturing space-optimized solutions improving operational efficiency for manufacturers, warehouses, retail, and logistics companies. Our vast network of distributors ensures a local expert supports each application. UNEX is an ISO-certified company committed to providing value and quality to our customers through:

A Customer-Focused Experience

Our goal is to exceed customer expectations through continuous improvement, customer service, and empowering our employees.

In-House Design & Manufacturing

UNEX provides free engineering support for all our products with one goal: to help customers make the most out of their existing space.

On-Time Shipping

We deliver what we promise. Over 99% of the orders UNEX ships arrive at their destination on time.

See Why Customers Love UNEX

"UNEX works with the customer to understand their unique business, rather than simply providing a quote on a job."

– Greg Miller | Crown

"The UNEX team is always responsive, helpful. And they have good products. I always feel confident when I'm working with a UNEX solution."

– Dave Holwerda | Account Manager | Morrison Industrial Equipment

"UNEX has worked with us for many years to help us maximize efficiencies in every area. When it came time to expand one of our regions, we spoke with UNEX first."

– Jim Thibeault | Operations Manager | Capital Candy

Resources

Solution Spotlight: SpanTrack Lane Carton Flow Rollers

What is Carton Flow? Carton flow, also known as flow racking, roller racking, and gravity flow racking, is a dynamic ...

Choosing Between Carton Flow Rollers and Wheel Beds

Material handling and SKU storage are central components of any warehouse operation. Efficiency is built on smart ...

Assembly Show South 2024: In Review

FlowCell modular flow racks were showcased in booth #1722! Every year, hundreds of exhibitors and thousands of ...

Maximizing Warehouse Efficiency in the Age of eCommerce Growth

Shopping from your phone or computer is easier than ever — eCommerce has dramatically transformed retail from only ...

Connect with an Expert

Get in touch with our team of space optimization experts to learn more about our industry-leading solutions.