Warehouse Space Optimization for Order Fulfillment

Maximize Efficiency with Order Fulfillment Solutions

The growing demand for warehousing facilities and order fulfillment centers makes it challenging for businesses to scale efficiently. With SKU proliferation and increased inventory requirements, warehouse managers face significant storage constraints. Additionally, more fulfillment center staff requires optimized workspaces to ensure operational efficiency.

So, how can warehouses and order fulfillment centers gain the additional space and storage they need while maintaining ROI? Instead of investing in additional warehouse space, optimizing existing warehouse storage solutions is the ideal approach. By implementing dynamic storage systems, facilities can maximize storage density and improve operational flow while maintaining a strong ROI.

Warehouse Storage

In today’s fast-paced and space-constrained warehouse environments, inefficiencies in storage layouts and SKU organization can lead to higher operational costs and reduced productivity. Effective warehouse storage solutions are essential to overcoming these challenges, ensuring optimal inventory accessibility and streamlined workflows.

UNEX offers warehouse storage solutions designed to tackle these challenges, offering improved organization, enhanced SKU accessibility, and better utilization of your facility's existing footprint.

UNEX Solutions for Warehouse Storage

UNEX delivers high-density, efficient warehouse storage solutions that optimize space, streamline inventory handling, and enhance operational flow. Our dynamic storage solutions ensure seamless SKU organization and quicker access for fast, medium, and slow-moving SKUs.

SpeedCell

SpanTrack

Pallet Track

Order Picking

A well-structured order picking process is essential for efficient order fulfillment. Poorly optimized picking workflows contribute to wasted time, increased labor costs, and order inaccuracies, ultimately affecting customer experience and operational efficiency. As eCommerce and omnichannel fulfillment continue to expand, businesses must implement streamlined strategies to ensure speed, precision, and scalability in their picking operations.

UNEX offers order picking solutions tailored to improve accuracy, reduce picker fatigue, and accelerate fulfillment speeds. By implementing high-density storage and material handling solutions, UNEX helps businesses enhance organization, minimize wasted movement, and optimize order throughput, ensuring a more productive and cost-effective operation.

UNEX Solutions for Order Picking

UNEX offers a range of order picking solutions to transform your order fulfillment process. By enhancing organization, condensing storage, and improving ergonomics, these dynamic storage solutions help warehouses reduce labor costs and boost order accuracy.

SpeedCartt

SpeedCell

SpanTrack

FlowCell

Ready To Connect With An Expert?

Fill out the form below to request a consultation to find the ideal order picking solutions for your unique space.

Packing Stations

Packing stations are essential hubs in the order fulfillment process where goods are packaged, labeled, and prepared for shipment. Optimizing packing stations ensures faster workflows, accurate order assembly, and improved worker ergonomics.

By integrating dynamic storage and material handling solutions, UNEX transforms packing areas into highly efficient, organized spaces that reduce errors and improve throughput.

UNEX Solutions for Packing Stations

UNEX offers tailored solutions to streamline packing operations, improve organization, and enhance worker productivity.

FlowCell

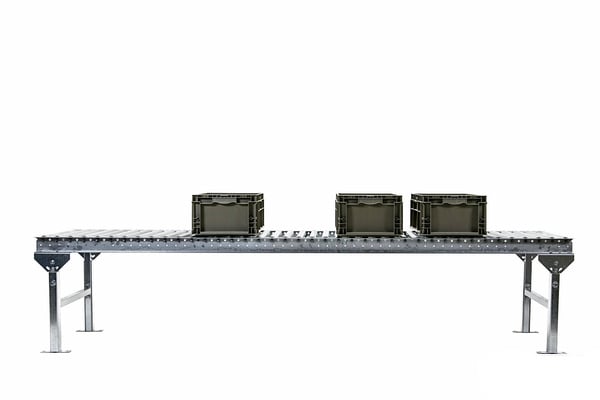

Gravity Conveyor

SpanTrack

Applications for Every Industry

Warehouse Storage Solutions

Order Picking

Case Picking

Each Picking

Resources

Explore All"FlowCell cut the length of our lines in half, which gave us the ability to increase the number of kitting and assembly lines from 18 to 28 in the same amount of floor space."

— Valerie Clements | Special Operations Team | Hello Fresh

"We’ve done business with UNEX for over 30 years. Their reputation for quality is bulletproof."

— Jim Thibeault | Operations Manager | Capital Candy Co.

"Pickers can clearly see the SKUs, which supports our goal of having a 0% mispick rate."

— Thomas Brown | Systems Engineer | Thermo Fisher Scientific

Connect with an Expert

Get in touch with our team of experts to learn more about our solutions.